Innovations

Mountain Hazelnuts, with technical assistance from international experts, uses technological and scientific innovations to tackle the challenges of producing a new crop in a rugged geography. The Company has shared several tools and practices with other mission-oriented companies working around the world.

TRACEABILITY VIA DIGITAL DATA COLLECTION

To support its global supply chain, Mountain Hazelnuts has developed an Android-based Remote Monitoring & Traceability system for digital reporting, called Field Companion. From cultivation of plantlets through the shipment of export products, hazelnuts are tracked at each step of the process. End consumers are able to see detailed information regarding the nuts they eat, ensuring a rare degree of traceability and transparency.

The Field Companion application is essential for monitoring thousands of geographically dispersed orchards, where real-time operational reporting is required for functions ranging from verifying land suitability to monitoring tree care to evaluating social and environmental impact. This sophisticated data collection system links local farmers to operational headquarters, enabling intervention from experts as necessary and the promulgation of best practices, while aggregating data for pattern analysis.

PLANT REPLICATION VIA TISSUE CULTURE

To optimize quality and productivity, the Company provides farmers with hazelnut trees best suited to the environment. A challenge is to grow millions of such trees with consistent quality, free from disease or defect. Historically, most hazelnut orchards are planted from seeds or cuttings, which are slower and less controlled methods of reproduction.

Tissue-culture techniques regenerate plants that are genetically identical to the original “mother” under sterile conditions. Tissue culture has several advantages:

Rapid exponential growth: Within one year, one plant can be replicated into hundreds of plants.

Controlled environment: Scientific processes in a lab environment produce consistent results, lowering mortality and increasing yields.

Year-round multiplication: Tissue culture continues each month, stabilizing production and insulating from seasonal cycles.

Mountain Hazelnuts has developed proprietary hazelnut tissue-culture know-how, which it applies in a well-established international tissue-culture lab.

GRAFTING AND POLLINATION

To improve orchard productivity through enhanced pollination, Mountain Hazelnuts has successfully completed major grafting programs across Bhutan in close collaboration with Bhutan’s Ministry of Agriculture and Forests. The scope and scale of these programs is among the largest and most complex ever undertaken, involving the selection and importation of scion wood from complementary hazelnut varieties from mature orchards in different parts of the world, involving rigorous phenological assessment and innovative treatments of plant material to eliminate contamination risk. Another critical aspect was building unbroken cold chain logistics from rural orchards in the Republic of Georgia and Australia where the scion wood was harvested, to distant orchards in the Himalayas, where the wood was ultimately grafted. High grafting success rates have been achieved in both orchards and Mountain Hazelnuts’ nurseries. More than 150 MH extension staff executed the program alongside 50 master grafters with the support of experts from the Ministry of Agriculture and Forests. In total, more than 5,000 acres of land have been grafted across 15 Dzongkhags. Over 425,000 grafts have been completed over the course of two years, making this one of the largest nut in-field grafting programs in the world.

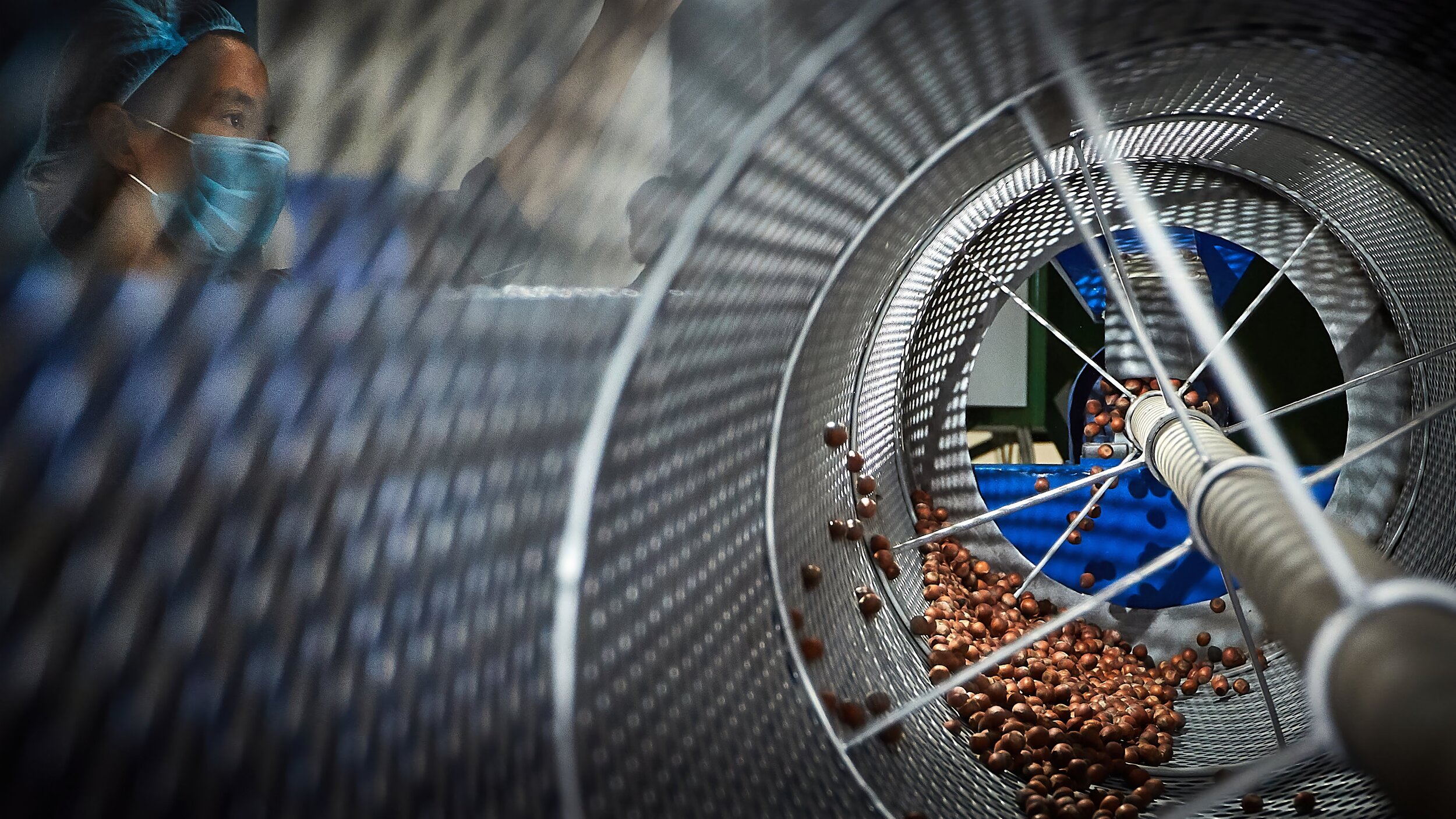

HAZELNUT DRYING SYSTEM OPTIMIZATION

The edible part of the hazelnut, the kernel, is inside the shell. If the kernel is not at a low enough moisture content, there could be various forms of spoilage that make it inedible, unattractive, or reduce its value. The main forms of potential spoilage are rancidity (unpleasant taste), spoilage by microorganisms, and shell staining. However, with timely and proper drying and storage, it is possible to store hazelnuts for more than one year without any reduction in quality.

To optimize the way nuts are handled, Mountain Hazelnuts works closely with grower partners to ensure that, once harvested, the following steps are taken:

remove from husks as soon as possible,

clean and separate from any foreign material such as mud, leaves, and twigs,

sun dry in orchards, and

transport to collection centers.

To ensure hazelnuts have a low moisture content and to protect against re-wetting, Mountain Hazelnuts has designed a low-cost, easily transportable drying unit, which operates on both solar and electric power, and is capable of reducing the moisture content of 200kg of nuts by 10% within 24 hours. This has enabled the Company to build and locate drying units at each harvest collection center across the country, to ensure that nuts are dried immediately upon collection, before even reaching the processing factory in Mongar. This optimized drying system has enabled the Company to ensure that hazelnuts sent for processing are of the highest quality and optimum moisture content.

RAINWATER IRRIGATION TANKS

Mountain Hazelnuts has also designed low-cost and easy to construct rainwater harvesting and irrigation tanks to ensure that orchards are well irrigated all year round, and especially in the dry winter months. These are custom designed to meet the needs of, and mitigate the challenges faced by grower partners.

The tanks are fitted with active release nozzles so that water only flows when the user presses on the nozzle. Water automatically stops flowing if growers are not using it, which is essential in minimizing water loss. This active release nozzle also avoids the problem of using open-hose pipes which deliver water much more quickly than the soil can absorb, causing runoff that wastes water and displaces precious topsoil.

In addition, tanks are custom fitted with low clearance roofs to prevent evaporation of water during the dry season.

Tanks are also easily attached to hose pipes to reach trees, avoiding carrying and potentially spilling.